|

Bioremediation Bioremediation

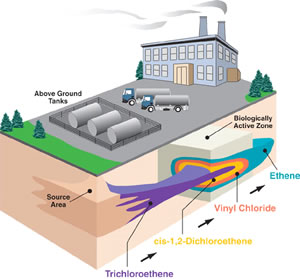

Innovative Engineering Solutions Inc. is a national leader in design and implementation of innovative remediation technologies. One of our main areas of specialization is Bioremediation. Simply stated- we are extremely good at what we do- we excel technically in this area and the combination of our technical, design, laboratory and most importantly practical common sense and experience makes us the best bioremediation firm in the US. We have experience with anaerobic, aerobic (using peroxide and pure oxygen; see an example in Massachusetts ), and co-metabolic (for 1,4 dioxane, MTBE and chlorinated VOCs) degradation.

IESI designed and implemented one of the first full-scale enhanced anaerobic dechlorination (EAD) systems in the United States (1997). Further, IESI was the lead design and implementation firm for the largest in-situ EAD system in the US (80 acres), and has implemented one of the largest full-scale bioaugmentation (addition of imported microorganisms) projects in the nation. We are currently operating a 44 acre dilute VOC bioremediation project that has received regulatory accolades and whose success is likely unmatched across the US. Over the past fifteen years, we have evaluated more than 200 sites and are involved in approximately 60 enhanced anaerobic dechlorination (also known as reductive dechlorination) projects in various stages of evaluation, design, pilot testing, and implementation.

The following bullets outline our approach to bioremediation and our success in adapting this technology to many sites.

- We are not tied to a single electron donor compound. We select the electron donor based upon site specific microcosm testing and evaluate the need for bioaugmentation. We have had great success with whey, alcohol and vegetable oil.

- If bioaugmentation is required, we bioaugment using a variety of cultures that we have developed over the past ten years. We have TCA (up to 200 ppm), PCE (up to 500 ppm), 1,4 dioxane, MTBE, 1,2 DCA and perchlorate degraders in our laboratory.

- We have had the most success with engineered systems to distribute cultures and/or amendments.

- We can avoid costly pilot tests and "mistakes" by designing the electron donor delivery system based upon our microcosm testing and a comprehensive understanding of the site hydrogeology. Our experience in this regard was presented at the at a recent Battelle Conference with the paper entitled "Microcosm Test + Hydraulic Test = Pilot Test", Fam, Pon & Mountain, 2006.

In addition to our PCE and TCA degrading NJ-14 culture, we have a propanotroph (SL-D), an organism that can utilize propane as a sole carbon source, from one of our project sites in Salt Lake City, Utah. SL-D can aerobically degrade at least 20 mg/L of 1,4 Dioxane within days. Our propanotrophic culture that degrades 1,4-dioxane can also co-metabolically degrade TCE, 1,1,1 TCA, and their daughter products. Our BW-05 MTBE (as sole carbon source) degrading culture can degrade over 40 ppm of MTBE within a few weeks.

Our experience in evaluation, testing, design and implementation of successful bioremediation programs/systems is unmatched. Please review some of our project summaries.

|